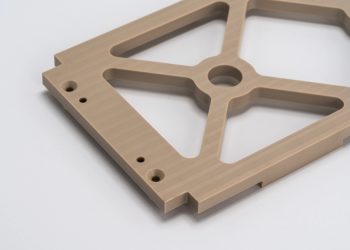

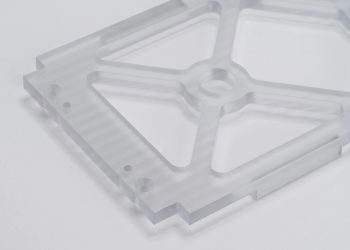

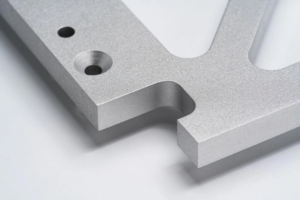

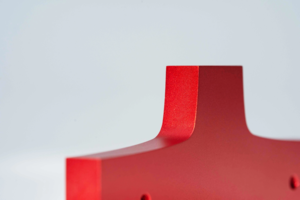

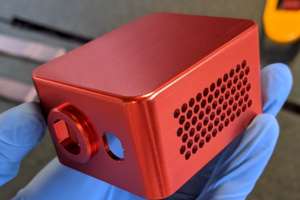

Aluminum alloys have good strength-to-weight ratio, high thermal and electrical conductivity, low density and natural corrosion resistance. Can be anodized.

Alloys

Aluminum 7075-T7351 | 3.4365 | 76528 | AlZn5.5MgCu

Aluminum 6061-T651 | 3.3211 | 65028 | AlMg1SiCu

Aluminum 7075-T651 | 3.4365 | 76528 | AlZn5.5MgCu

Aluminum 6082-T651 | 3.2315 | 64430 | AlSi1MgMn

Aluminum 6060 | 3.3206 | AlMgSi

Aluminum 5052 | EN AW-5052 | 3.3523 | AlMg2,5

Aluminum 2017A | 3.1325 | 24530 | AlCu4MgSi

Aluminum 2014 | 3.1255 | 24345 | AlCu4SiMg

Aluminum 6063 | EN AW-6063 | 62400| AlMg0,7Si

Aluminum 7050 | EN AW-7050 | 3.4144| AlZn6CuMgZr

Aluminum 2024-T351 | 3.1355 | 24530 | AlCu4Mg1

Aluminum MIC6

Aluminum 7075-T6 | 3.4365 | 76528 | AlZn5,5MgCu

Aluminum 5083-h111 | 3.3547 | 54300| AlMg4.5Mn0.7

Aluminum 6082 | 3.2315 | 64430| AlSi1MgMn

Aluminum 6061-T6 | 3.3211| 65028| AlMg1SiCu

Show all alloys

Aluminum 6061-T651 | 3.3211 | 65028 | AlMg1SiCu

Aluminum 7075-T651 | 3.4365 | 76528 | AlZn5.5MgCu

Aluminum 6082-T651 | 3.2315 | 64430 | AlSi1MgMn

Aluminum 6060 | 3.3206 | AlMgSi

Aluminum 5052 | EN AW-5052 | 3.3523 | AlMg2,5

Aluminum 2017A | 3.1325 | 24530 | AlCu4MgSi

Aluminum 2014 | 3.1255 | 24345 | AlCu4SiMg

Aluminum 6063 | EN AW-6063 | 62400| AlMg0,7Si

Aluminum 7050 | EN AW-7050 | 3.4144| AlZn6CuMgZr

Aluminum 2024-T351 | 3.1355 | 24530 | AlCu4Mg1

Aluminum MIC6

Aluminum 7075-T6 | 3.4365 | 76528 | AlZn5,5MgCu

Aluminum 5083-h111 | 3.3547 | 54300| AlMg4.5Mn0.7

Aluminum 6082 | 3.2315 | 64430| AlSi1MgMn

Aluminum 6061-T6 | 3.3211| 65028| AlMg1SiCu

Stainless steel alloys have high strength, ductility, wear and corrosion resistance. They can be easily welded, machined and polished.

Alloys

Stainless steel 416 | 1.4005 | X12CrS13

Stainless steel 15-5 | 1.4545 | X5CrNiCu15-5

Stainless steel 301 | 1.4310 | X10CrNi18-8

Stainless steel 430 | 1.4016 | X6Cr17

Stainless steel 440C | 1.4125 | X105CrMo17

Stainless steel 420 | 1.4028 | X30Cr13

Stainless steel 304/304L | 1.4301/1.4307 | X5CrNi18-10/X2CrNi18-9

Stainless steel 2205 Duplex | 1.4462 | 2205 | X2CrNiMoN 22-5-3

Stainless Steel 17-4 PH | 1.4542 | X5CrNiCuNb16-4 - Annealed state

Stainless steel 303 | 1.4305 | X8CrNiS18-9

Stainless steel 316/316L | 1.4401/1.4404 | X5CrNiMo17-12-2/X2CrNiMo17-12-2

Show all alloys

Stainless steel 15-5 | 1.4545 | X5CrNiCu15-5

Stainless steel 301 | 1.4310 | X10CrNi18-8

Stainless steel 430 | 1.4016 | X6Cr17

Stainless steel 440C | 1.4125 | X105CrMo17

Stainless steel 420 | 1.4028 | X30Cr13

Stainless steel 304/304L | 1.4301/1.4307 | X5CrNi18-10/X2CrNi18-9

Stainless steel 2205 Duplex | 1.4462 | 2205 | X2CrNiMoN 22-5-3

Stainless Steel 17-4 PH | 1.4542 | X5CrNiCuNb16-4 - Annealed state

Stainless steel 303 | 1.4305 | X8CrNiS18-9

Stainless steel 316/316L | 1.4401/1.4404 | X5CrNiMo17-12-2/X2CrNiMo17-12-2

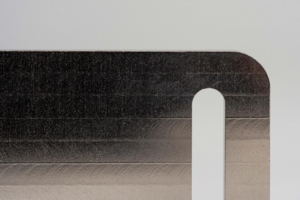

Mild steels are low-carbon metal alloys offering good mechanical properties, machinability and weldability at low cost. Can be carburized to increased hardness.

Alloys

Mild steel S275JR | 1.0044 | Fe430B | IS2062

Mild Steel S235JR | 1.0038 | Fe 360 B

Carbon steel C45 | 1.0503 | 1045 | EN8

Mild steel S355J2 | 1.0577 | 1522H | Fe 510 D

Mild steel 1045 | 1.0503 | C45 | EN8

Mild steel A36 | 1.025 | Fe 410

Mild steel 1018 | 1.1147 | C18 |16Mn

Mild Steel S235JR | 1.0038 | Fe 360 B

Carbon steel C45 | 1.0503 | 1045 | EN8

Mild steel S355J2 | 1.0577 | 1522H | Fe 510 D

Mild steel 1045 | 1.0503 | C45 | EN8

Mild steel A36 | 1.025 | Fe 410

Mild steel 1018 | 1.1147 | C18 |16Mn

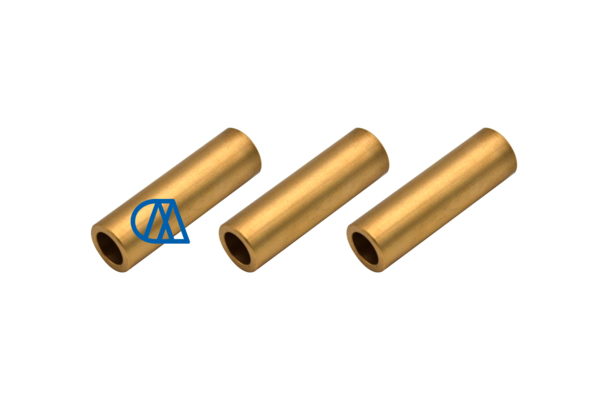

Brass is a metal alloy with good machinability and excellent electrical conductivity. Ideal for applications that require low friction.

Alloys

Brass Cz121 | C38500 | 2.0401 | CuZn39Pb3

Brass C360 | 2.0375 | CuZn36Pb3 | 319 grade 2

Brass C360 | 2.0375 | CuZn36Pb3 | 319 grade 2

Copper offers excellent thermal and electrical conductivity, it's often used for busbars, wire connectors, and other electrical applications. Copper has a glossy reddish-orange appearance.

Alloys

Copper C101 | CU OFE

Copper C110 | CU ETP

Copper C110 | CU ETP

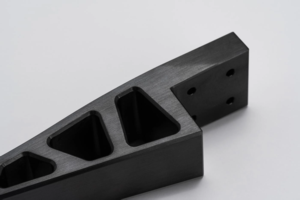

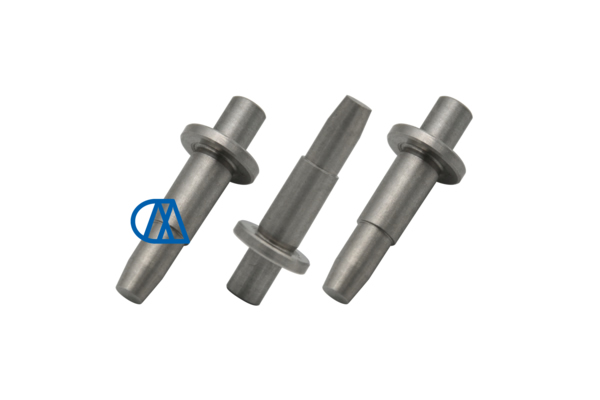

Alloy steels contain other alloying elements in addition to carbon, resulting in improved hardness, toughness, fatigue and wear resistance.

Alloys

Alloy steel 1.7131 | 16MnCr5

Alloy steel 1215 | EN1A | 1.0715

Alloy steel 4340 | 1.6511 | 36CrNiMo4 | EN24

Alloy steel 4140 | 1.7225 | EN19 | 42CrMo4

Alloy steel 1215 | EN1A | 1.0715

Alloy steel 4340 | 1.6511 | 36CrNiMo4 | EN24

Alloy steel 4140 | 1.7225 | EN19 | 42CrMo4

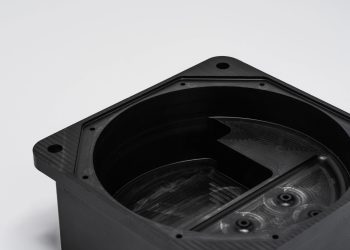

Tool steels are metal alloys with exceptionally high hardness, stiffness and abrasion resistance. Suitable for manufacturing industrial tools.

Alloys

Tool steel A3 - Annealed state

Tool steel h13 | 1.2344 | X40CrMoV5-1 - Annealed state

Tool steel S7 | 1.2355 | 50CrMoV13-15 - Annealed state

Tool steel O1 | 1.2510 | 100MnCrW4 - Annealed state

Tool steel A2 | 1.2363 | X100CrMoV5-1- Annealed state

Tool steel D2 | 1.2379 | X153CrMoV12-1 - Annealed state

Tool steel h13 | 1.2344 | X40CrMoV5-1 - Annealed state

Tool steel S7 | 1.2355 | 50CrMoV13-15 - Annealed state

Tool steel O1 | 1.2510 | 100MnCrW4 - Annealed state

Tool steel A2 | 1.2363 | X100CrMoV5-1- Annealed state

Tool steel D2 | 1.2379 | X153CrMoV12-1 - Annealed state

Titanium is a metal with excellent strength-to-weight ratio, low thermal expansion and high corrosion resistance that is sterilizable and biocompatible.

Alloys

Titanium Grade 5 | 3.7164 | Ti6Al4V

Titanium Grade 2 | 3.7035

Titanium Grade 1 | 3.7025

Titanium Grade 2 | 3.7035

Titanium Grade 1 | 3.7025

Inconel is a high-strength, corrosion-resistant nickel alloy. Ideal for aerospace applications.

Alloys

Inconel 718

+86 13416744140

+86 13416744140

We can source any other material on request, but quotes take up to 48 hours.

We can source any other material on request, but quotes take up to 48 hours.

Phone: +86 13416744140

Phone: +86 13416744140  Add: No.108, BaXin Rd, Wanjiang District, Dongguan City, Guangdong Province,China

Add: No.108, BaXin Rd, Wanjiang District, Dongguan City, Guangdong Province,China